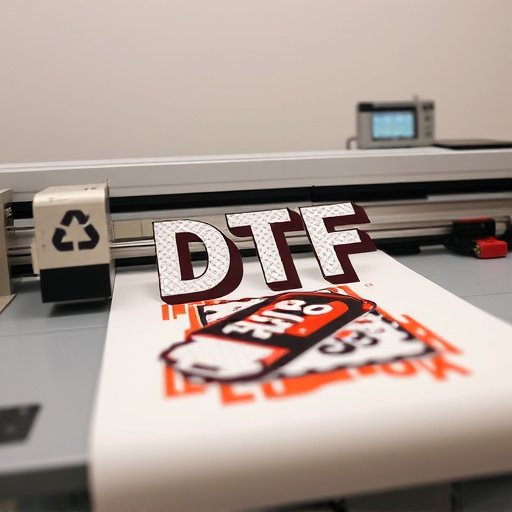

Small businesses can now compete effectively in saturated markets using Direct-to-Film (DTF) inks, which enable them to produce high-quality, personalized products with intricate designs on various surfaces. DTF printing streamlines production and offers vibrant multi-color designs in a single pass, appealing to shops looking to expand their product range or engage in custom apparel production. DTF inks provide a cost-effective and efficient method for custom graphic tee printing, allowing businesses to offer competitive pricing without sacrificing quality while ensuring quick turnaround times for time-sensitive orders. This technology gives small shops a significant advantage in meeting customer demands and thriving in the competitive landscape of custom tee production.

In today’s competitive marketplace, small shops often find themselves at a disadvantage when competing with larger businesses. However, Digital Transfer (DTF) inks emerge as a powerful tool to level the playing field. This article explores how DTF inks enable small retailers to thrive in big markets by offering cost-effective, versatile printing solutions. From quick turnaround times and customization options to building local brand recognition, we’ll delve into the strategies that empower small businesses to succeed using DTF ink technology.

- The Advantage of DTF Inks for Small Shops

- – Cost-effectiveness and efficiency

- – Versatility in printing methods

The Advantage of DTF Inks for Small Shops

Small shops and local businesses often find themselves at a disadvantage when competing with larger corporations in saturated markets. However, the advent of Direct-to-Film (DTF) inks has levelled the playing field, empowering these smaller entities to create high-quality, personalized products that can rival those of their bigger counterparts. DTF printing offers unparalleled versatility, allowing businesses to print intricate designs and complex graphics directly onto a variety of surfaces, from light fabrics like t-shirts to sturdy hoodies.

One of the key advantages of DTF inks is their ability to streamline production processes, especially for bulk orders. Unlike traditional printing methods that require separate setup stages for each color, DTF technology allows printers to achieve vibrant, multi-color designs with just a single pass through the printer. This not only saves time but also reduces costs, making it an attractive option for small shops looking to expand their product offerings or engage in custom apparel production, such as direct to film personalized hoodies.

– Cost-effectiveness and efficiency

DTF (Direct to Fabric) inks offer small shops a powerful tool to compete in big markets by providing an incredibly cost-effective and efficient method for custom graphic tees printing. This technology allows businesses to produce high-quality, vibrant designs directly on various fabrics, eliminating the need for costly set-up fees and lengthy production times associated with traditional printing methods. As a result, small shops can offer competitive pricing without compromising on quality, making them attractive alternatives for customers seeking affordable yet personalized merchandise.

Moreover, DTF inks streamline the entire process from design to print, enabling quick turnaround times. This efficiency is particularly beneficial for time-sensitive orders or when dealing with last-minute requests, ensuring that small shops can meet customer demands and maintain a competitive edge in the market. With their ability to deliver professional results and minimize waste, DTF printing has become a preferred choice for businesses looking to thrive in the competitive landscape of custom graphic tees production.

– Versatility in printing methods

The versatility of DTF (Direct to Fabric) inks is one of its key advantages, allowing small shops to compete in big markets. Unlike traditional printing methods that often require specialized equipment and limited material choices, DTF offers a dynamic range of application options. It can be used for various fabrics, from cotton tees to polyester jackets, making it an excellent choice for businesses looking to cater to diverse customer preferences. This adaptability also extends to design complexity; DTF inks handle intricate patterns and vibrant colors with ease, ensuring that small shops can create visually appealing products without the need for extensive set-up times or specialized skills.

Furthermore, the efficiency of DTF printing is a significant draw for small businesses. With quick drying times and direct application onto fabrics, it reduces production delays compared to heat press methods. This speed allows shops to take on custom orders promptly, catering to the fast-paced demands of today’s market. When combined with the right DTF ink and best printer options available, such as those designed for DTF for Apparel, small businesses can offer competitive pricing while maintaining high-quality outputs, solidifying their presence in even the busiest retail landscapes.

DTF inks offer a game-changing solution for small shops aiming to compete in big markets. By providing cost-effectiveness, efficiency, and versatility in printing methods, these inks enable businesses to produce high-quality products swiftly and profitably. Adopting DTF technologies can be a strategic move for small retailers looking to enhance their competitive edge and thrive in today’s dynamic market landscape.